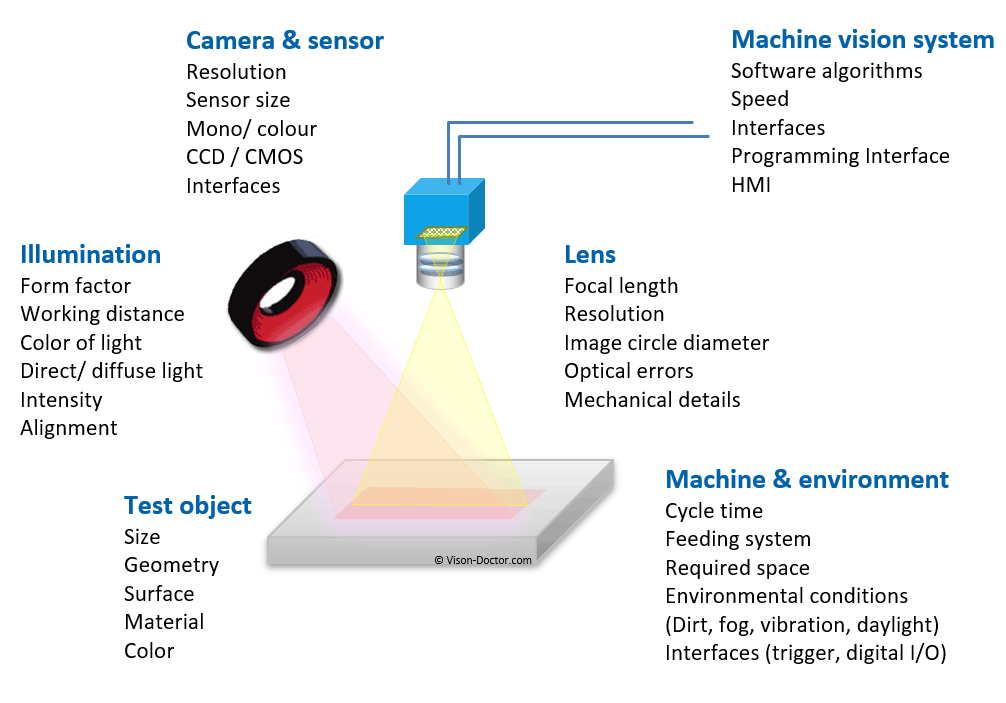

Before a system is selected, you should clearly define all your requirements for the machine vision system. Not all criteria can be met by all system types so that the choice is quickly narrowed down to the appropriate test system. The Starting point for this consideration is the object to be inspected and the process environment in which the system must be installed. Detailed knowledge of this is essential to establish a stable plant process and to implement an economically viable application. The complete "practice" section of this website is supposed to help you in making the right decisions. In particular, the section "Requirement & System specification" provides an additional list of questions.

A variety of basic conditions and parameters must be weighed for the selection of the image processing system:

There are many questions that need to be answered before you can decide which camera system will meet your needs. For this purpose the camera system must never be treated alone, but it is also considerably defined by the underlying conditions (inspected part / plant). Only the successful selection and the interaction of ALL individual machine vision hardware components together with the software ensure success!

Vision-Doctor.com is a private, independent, non-commercial homepage project and not a technology provider or system integrator. Suitable technologies and further professional support can be obtained from the companies & partners listed below.

If necessary, I will be happy to provide a quick recommendation, contacts and brief information.