Illumination

Diffuse incident lighting

Light with diffuser, coaxial lighting, tunnel, dome lighting

Diffuse light is required for many applications where reflective, polished, shiny or metallic objects need to be inspected. This becomes particularly difficult when these surfaces are no longer perfectly flat, but freely shaped, bent, curved or cylindrical.

Inspection then requires diffuse lighting. This is what is used:

Comparison of diffuse illumination techniques

Diffuse ring light

Coaxial illumination

Dome illumination

Diffuse ring light

Coaxial illumination

Dome illumination

Incident light with diffuser

For example, the individual LEDs are no longer visible on a reflective material. However, the light is still highly directional and comes mainly from the direction of illumination.

Coaxial incident light illumination (on-axis illumination)

In this type of illumination, light is coupled into the optical path from the side (coaxially). This is achieved by using a semi-transparent mirror that is illuminated from the side and directs the light downwards onto the specimen. The specimen reflects the light through the semi-transparent mirror to the camera.

The advantage of this type of illumination is that you can 'see' through the light source (in this case the mirror). The image appears very homogeneous overall and only shows a general linear loss of light the further away the mirror is from the lamp. Tip: The illumination must be significantly larger than the area to be tested to avoid inhomogeneities in the illumination.

Coaxial illumination is ideal for highly reflective materials with a relatively flat surface. It is very homogeneous, but fairly directional, and produces contrast at edges and stronger curvatures.

Working distances for coaxial illumination are short, from 1 cm to a maximum of 3 cm.

Rule of thumb: The closer the better if you want to take advantage of the diffuse nature of the lighting for soft illumination!

The further away the light is, the more the soft illumination of the scattered light is lost and the light becomes more directional. Bevels, notches, imperfections, etc. that are no longer completely flat will be emphasised even more.

Working principle coxaxial illumination

Direct light

Brushed metal and scratches create strong reflections. The display still shows inhomogenities although it was tilted slightly to avoid harsh total reflections. Light is highly directional.

Diffuse light

Material is illuminated quite homogeneous. Scratches on metal still easily recognizable. Many fine scratches are gone. Even more diffuse illumination with dome illumination would be possible.

Dome-like lighting

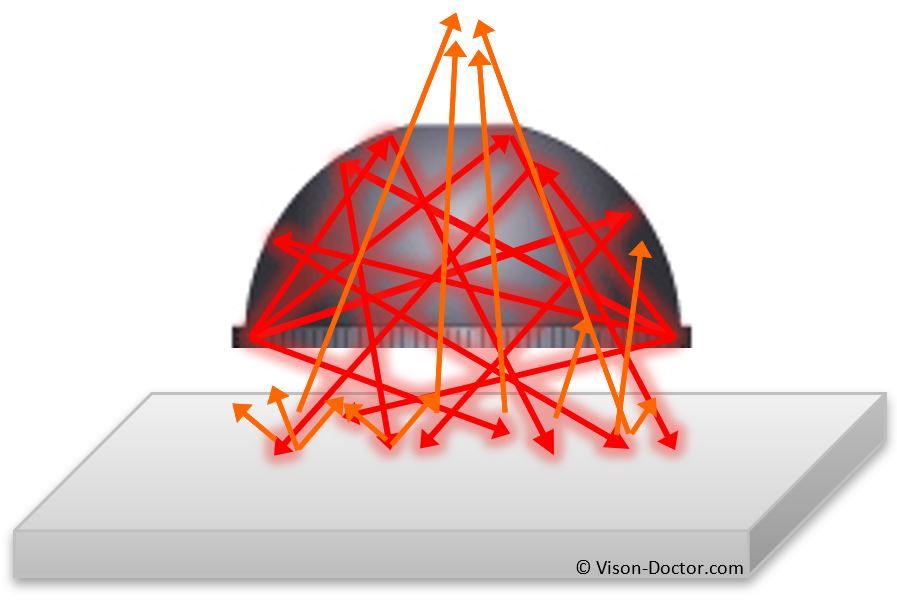

Only dome lighting can produce truly diffused light with virtually no reflections on the component. With light coming from all directions, even imperfections and scratches are softly illuminated and uniform materials appear homogeneous.

Direct light

Matt sheet metal angle creates reflections. Light is highly directional.

Diffuse dome light

Material is extremely homogeneously illuminated Scoring on metal barely recognizable. Surface defects no longer visible.

Dome & Tunnel

Dome lights are ideal for inspecting metallic and shiny materials as they suppress reflections.

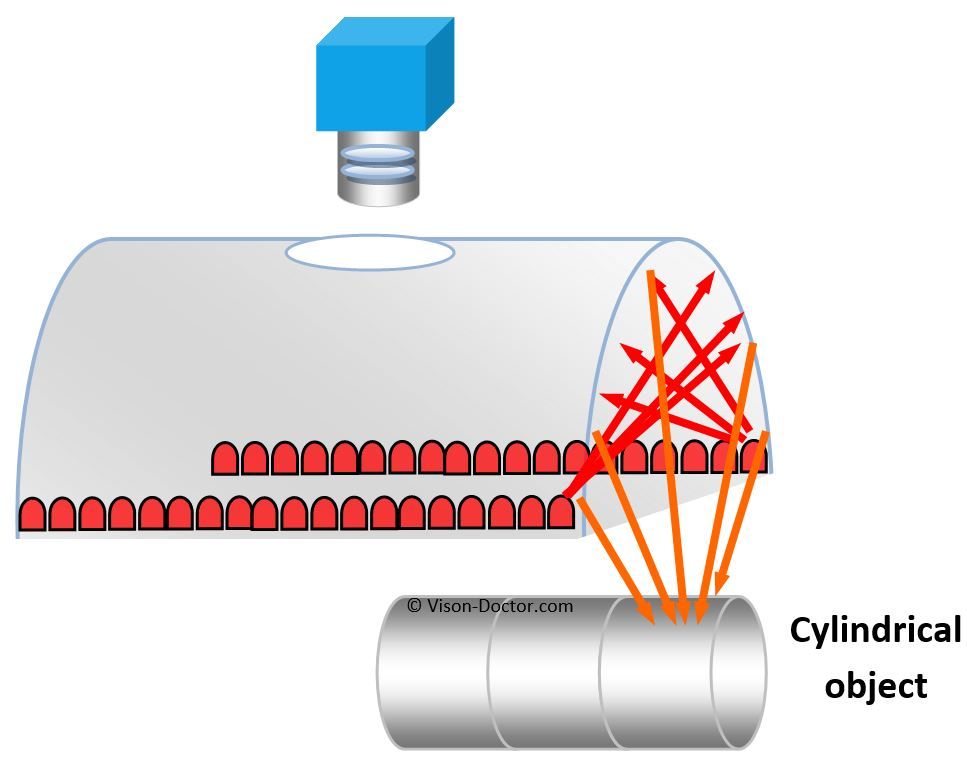

Variations of this illumination include slightly curved lights, which can illuminate a much smaller solid angle, or tunnel-like dome lights, which have an elongated dome shape and are ideal for illuminating cylindrical objects.

Dome illumination

Tunnel illumination

Influence of the working distance

If you want to illuminate a component as diffusely as possible, you should generally choose a short working distance. The further away you move the lighting, the more directional the light will appear. As a result, the solid angle illuminated by the lighting becomes smaller. More curved objects will no longer be illuminated.

Some examples of a curved shower gel bottle as the working distance increases:

Dome with 5 mm distance

Curved surface nearly complete illuminated homogeneously. Ideal for print inspection.

Dome with 50 mm distance

More and more peripheral areas are no longer bright, and more and more lateral light components are missing for homogeneous illumination.

Dome with 100 mm distance

Small solid angle that the lighting can still illuminate homogeneously. Half of the label is displayed dark.

Need machine vision lighting ?

Vision-Doctor.com is a private, independent, non-commercial homepage project and not a technology provider or system integrator. Suitable technologies and further professional support can be obtained from the companies & partners listed below.

If necessary, I will be happy to provide a quick recommendation, contacts and brief information.