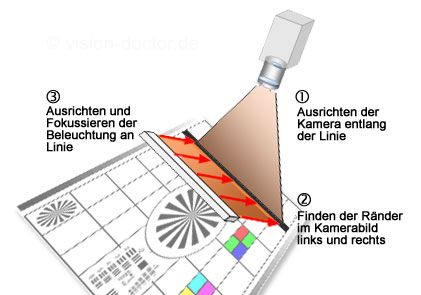

Ultimately, only a thin line of light is required to illuminate a line scan camera application, as only one, two or four (or in extreme cases up to 196 pixels: TDI) wide lines are captured by the sensor. However, it is important for all line scan camera applications that the light is as bright as possible and extremely high frequency to avoid image flicker.

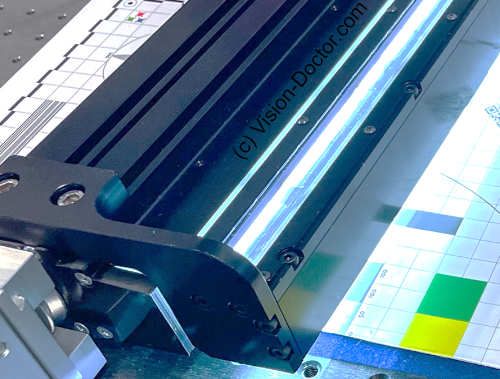

Today, LED line lights are used almost exclusively. In the early days, high-power LED line lights were actively cooled with water or fans, but today they are usually passively cooled. However, good heat dissipation through a metallic mounting surface is still important today.

Combinations of different techniques are also possible with line scan camera systems. For example, a colour line scan camera can simultaneously use illumination for incident light and blue illumination for transmitted light. This means that both image information is available at the same time.

Sequential acquisition one after the other (e.g. bright field, then dark field) are also possible with some line scan cameras, but require very fast illumination strobe controller. Then only every second line has to be extracted into a separate image. That's it!

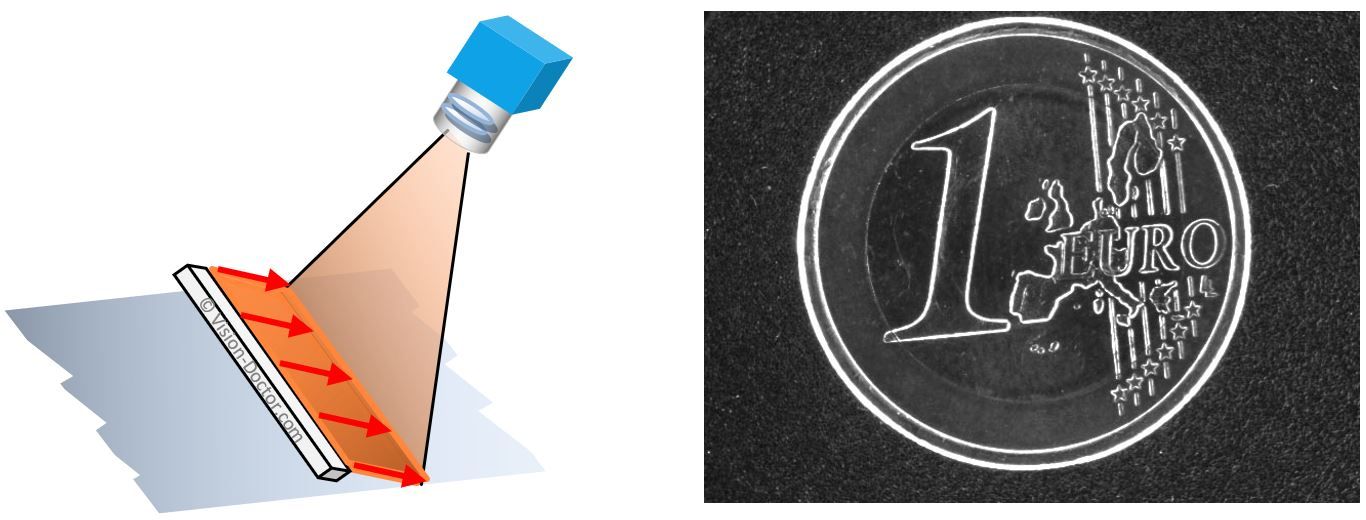

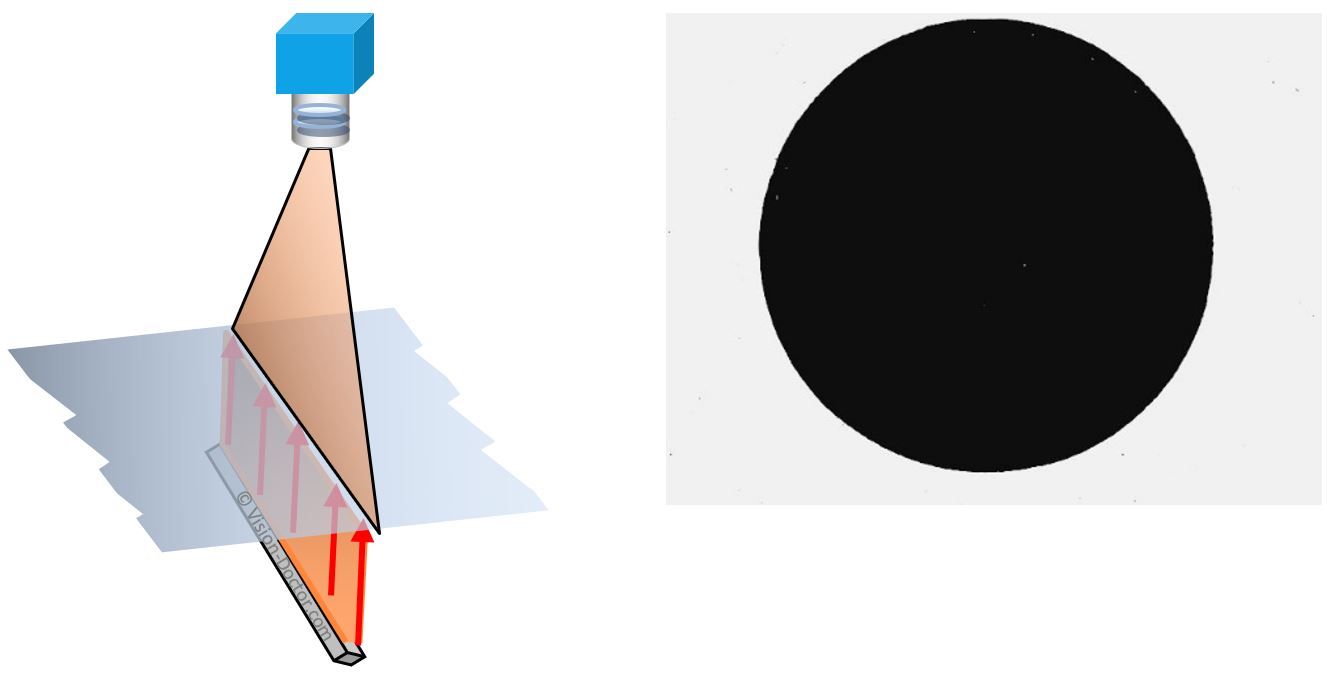

Line scan cameras can also be used to create a dark field effect. The illumination is not positioned on the component at the angle of reflection, but much flatter.

The directly reflected light does not hit the camera and the image field appears dark.

Only the weak scattered light is detected by the camera, so a lot of light is needed for this technique.

Scratches, slits, bumps or embossments appear bright because they scatter light due to their uneven surface. Ideal for detecting surface defects on smooth materials.

The line scan camera often only captures a strip of the image field that is a few 1/10 mm wide. This has to be precisely hit and illuminated by a very thin strip of light:

Vision-Doctor.com is a private, independent, non-commercial homepage project and not a technology provider or system integrator. Suitable technologies and further professional support can be obtained from the companies & partners listed below.

If necessary, I will be happy to provide a quick recommendation, contacts and brief information.