CAMERA

Camera detectors and spectral ranges

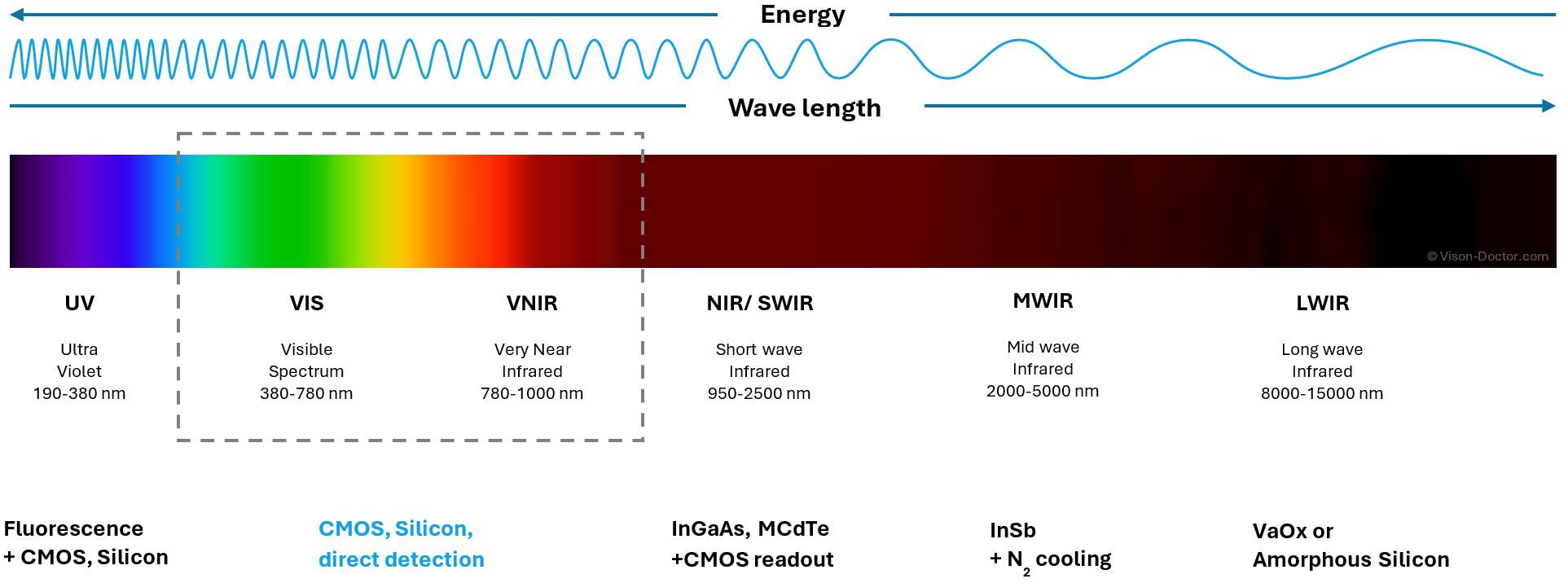

Modern sensor technologies, based on different detector technologies, enable the precise detection and analysis of information across the entire electromagnetic spectrum, from high-energy X-rays to long-wave infrared (LWIR).

In addition to traditional CMOS sensors for inspection in the visible range, spectral detectors, previously used primarily in science, are increasingly being used in various industrial applications.

These advanced methods are used in areas ranging from medical imaging and classical industrial in-line inspection to applications in agriculture (precision farming), mining and waste sorting.

As the number of applications grows, more exotic technologies are becoming more widely accepted, industrially viable and affordable.

Inspecting in different spectral range

X-ray spectral detection

Principle: Uses high energy photons to penetrate materials and produce high contrast images.

Applications: Non-destructive testing (NDT), airport security. Dental radiology, mammography, orthopaedic and surgical radiology, and scientific applications in biomedicine and materials analysis.

UV spectral detection

Principle: Detection of UV radiation used for analysing organic materials and biological samples.

Applications: Forensics, quality control in the food industry, examination of astronomical objects, etc

VIS Spectral Detection

Principle: Uses the visible spectrum to capture colour and intensity information.

Applications: Image processing, colour measurement, all kinds of optical inspection, such as attendance rolls, measurement application, text recognition, code reading, pick & place etc. The main part of all industrial image processing applications.

NIR spectral detection

Principle: Detection of near infrared radiation for chemical composition analysis and materials testing.

Applications: Spectroscopy, medical diagnostics, environmental monitoring. Hyperspectral imaging applications.

MWIR spectral detection (mid infrared)

Principle: Detection of mid-infrared radiation (3-5 µm), which is particularly sensitive to changes in temperature and chemical composition.

Applications: Gas detection and analysis, industrial process monitoring, military applications, thermography to detect leaks and insulation defects. Hyperspectral applications in 'black plastics, rubber, mining, contamination'.

LWIR spectral detection

Principle: Uses long-wave infrared radiation to measure temperature and capture thermal images.

Applications: Thermography in the temperature range from -10°C to 140°C, industrial process monitoring and NTD (non-destructive testing) applications. Active thermography (short-term excitation by an energy source such as heat flash or ultrasound, etc.) can be used to monitor cooling-down processes. Delaminations, cracks in the material and poor mechanical connections interrupt the heat flow and become visible.

Sensor types for different ranges of the electromagnetic spectrum

X-ray detectors based on scincillators

There are several technologies for detecting X-rays and converting the information into visible radiation. One of these is solid-state scintillators coupled to CMOS sensors. Solid-state scintillators are materials that emit visible or ultraviolet light after interacting with ionising radiation. When an X-ray photon strikes the scintillator, a photoelectric effect occurs. The resulting photoelectron transfers its energy to the surrounding electrons, which then return to their energy level and emit characteristic radiation in the form of visible or ultraviolet light.

These photons are detected by the photodiode of a CMOS sensor, which generates an electrical signal. Commonly used materials are cadmium tungstate and gadolinium oxysulphide.

UV-sensitive CMOS sensors

In the past, detection of shortwave UV radiation with conventional CCD camera technology was very limited. The sensor cover glass was then removed and partially replaced with quartz glass, as conventional glass blocks short-wave UV.

With specially coated fluorescent layers on the chip surface, the UV radiation could be detected and converted into a wavelength that could be detected by the sensor.

This is now much easier. Due to the good UV sensitivity of CMOS BSI (backside illuminated) camera sensors, the standard monochrome sensor SONY IMX536 can also be used for UVA applications (315-400 nm).

For UVB (280-315 nm) and UVC (<280 nm) imaging, the SONY IMX487 offers a much higher quantum efficiency and is therefore a very good choice.

CMOS sensors for VIS and VNIR

Modern, conventional CMOS sensors can traditionally be used to inspect in the visible spectrum (VIS) between 400 and 700 nm. Monochrome camera sensors provide intensity data (typically 8 bit, up to 12 bit for standard uncooled cameras).

The same sensors are also available as RGB colour camera sensors with a colour filter mosaic, which can then provide an RGB colour image after debayering in the camera.

The monochrome versions can also be used in the spectral range up to 1000 nm (VNIR = Very NEAR Infrared) without any special modifications.

Simple IR illumination with infrared LEDs in the 850 to 920 nm range and IR-compatible optics matched to the coating are sufficient for cost-effective IR applications.

InGaAs-Detektoren für NIR/ SWIR

Ein besonders leistungsfähiger Infrarotsensor, der in den letzten Jahren an Bedeutung gewonnen hat, basiert auf Indium-Gallium-Arsenid, oft abgekürzt als InGaAs. InGaAs ist für Infrarotlicht in einem Wellenlängenbereich empfindlich, der für viele Anwendungen relevant ist, insbesondere im nahen Infrarot (NIR) je nach Detektor zwischen 0,9 und 2 Mikrometern. InGaAs-Infrarotsensoren funktionieren wie Sensoren im sichtbaren Bereich auf der Grundlage des photoelektrischen Effekts. Wenn Infrarotlicht auf den Sensor trifft, werden Elektronen im Halbleitermaterial angeregt und bewegen sich. Dies erzeugt ein elektrisches Signal, das proportional zur Intensität der einfallenden IR-Strahlung ist. Als Ausleseschaltung wird auch bei diesen Sensoren ein klassischer Global Shutter CMOS-Sensor verwendet, der mit Hilfe von Indium-Bumps oder heute auch Kupferstrukturen mit der IR-empfindlichen InGaAs-Schicht kontaktiert wird. InGaAs-Sensoren sind heute "von der Stange" bis 5 Megapixel verfügar.

Detector units for medium wave infrared (MWIR)

The detection of electromagnetic radiation in the range of 3 to 5 micrometres is associated with increased effort.

Semiconductor materials such as InSb (indium + antimony) can detect these wavelengths, but require complex cooling of the sensor with liquid nitrogen at temperatures of around -196 degrees Celsius.

XBn-InAsSb detectors are a type of infrared detector based on the nBn structure and consist of the materials indium arsenide selenide (InAsSb) and aluminium arsenide selenide (AlAsSb). Barrier band technology is used in these detectors to improve performance and reduce dark current. They are often used in the 3.6 to 4.2 µm range. They ‘already’ work in the high temperature range of around 150 Kelvin, i.e. ‘only’ at -123 degrees Celsius.

That sounds complex and expensive - and it is. These are not simple camera sensors, but entire detector assemblies with active cooling.

This sounds complex and expensive - and it is. These are not simple camera sensors, but entire detector assemblies with active cooling.

In addition to many military applications (there are also special industrial applications that cannot be realised in any other way). Depending on the technology, these cameras can also be used for high-speed thermal imaging monitoring. Crack detection with active thermography on metals only works with very fast thermal imagers because metals conduct heat very quickly. Finally, certain organic materials and substances (including certain minerals) absorb only in the MWIR spectrum. For example, because black plastics are coloured with black carbon, such plastics cannot be spectrally distinguished and separated in recycling in the NIR, but they can be in the MWIR.

Microbolometer for long-wave infrared (LWIR)

Long-wave infrared (LWIR) refers to the wavelength range of approximately 8 to 15 micrometres (µm). LWIR detectors, also known as thermal imaging cameras, capture the thermal radiation emitted by objects and convert it into visible images. This technology is used in a wide range of applications, from surveillance and security to industrial process control.

Microbolometers are the most common detectors for LWIR. They consist of a material whose electrical resistance changes when heated by incident infrared radiation. The detection of light information is therefore not based on a photonic effect, but on a change in resistance. This change is measured and converted into an electrical signal. Microbolometers are very sensitive but have a relatively slow response time.

Typical sensor resolutions are QVGA, VGA up to megapixel sensors. Optics are often made of germanium and must be calibrated to the camera. It is therefore not possible to simply replace the optics.

Common frame rates for microbolometer sensors are 30 to 60 Hz, and the smallest temperature jump that can be detected (thermal resolution NETD) is often 30 to 40 mK. Cameras with a frame rate of 9 Hz are also often offered, as these are not subject to dual-use regulations and do not cause problems when exported to most countries in the world. ("Wassenaar Arrangement". Products, technologies or software must not be used for the development, production or use of nuclear, chemical or biological weapons or missiles).

Need to buy the right camera?

Vision-Doctor.com is a private, independent, non-commercial homepage project and not a technology provider or system integrator. Suitable technologies and further professional support can be obtained from the companies & partners listed below.

If necessary, I will be happy to provide a quick recommendation, contacts and brief information.