Camera

In-camera image optimisation

High-quality, modern industrial cameras equipped with a larger FPGA offer the user a wide range of image enhancements after the image has been captured. In this way, the user can obtain better images that show the most interesting image content in an even better way.

Another important function is the removal of defective or faulty pixels in the image, or even the conversion of the image data into a new data format. This could be colour space conversion, Stokes parameter calculation or even jpg compression.

Lookup Tables (LUTs)

LUTs allow the brightness information of each pixel to be translated into a new value. This can be done by creating and describing a table that specifies which grey tone (from 0 to 255 for an 8-bit monochrome camera) is assigned which target value. A LUT is nothing more than a double register. The IN values (0 to 255, i.e. the current grey values of each pixel) are replaced 1:1 by the fixed value of the OUT values (also an array with 256 values).

A wide range of image manipulations can be performed in this way, even if the camera does not have dedicated greyscale functions.

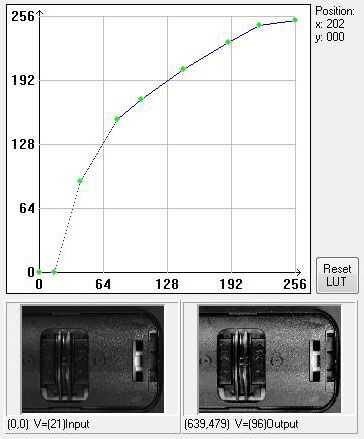

Manual gamma curve correction using LUTs

Dark grey tones in the image are strongly spread out and thus made visible.

Complete image inversion using La UT

Grey tone distribution was inverted.

Shading correction

Shading correction aims to minimise differences in brightness and colour caused by uneven lighting or optical distortion.

Typical causes are

- Vignetting effects of the camera lens

- Too little or uneven illumination due to a design that does not evenly illuminate the entire image.

- Shading effects caused by microlenses on CMOS sensors that are very large compared to the camera's lens mount (C-mount / F-mount, etc.). Microlenses on the pixels at the edge of the sensor also cause vignetting due to oblique incidence of light. This results in severe image vignetting.

Shading correction can compensate for this light gradient. Modern cameras can do this directly. This functionality is also referred to as bright image calibration, light gradient correction, field of view balance, etc.

This correction is particularly useful in applications where uniform illumination and colour fidelity are critical.

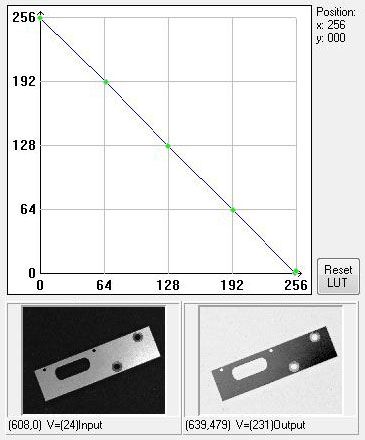

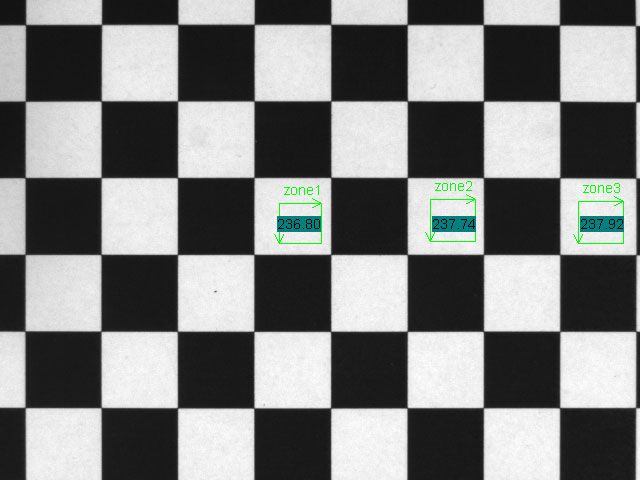

Original image with shading

Strong loss of brightness at the edges due to the ring light being too small. Bright areas with 40% difference in brightness.

Image after shading correction

Shading correction has been applied to the image. Grey tones now appear homogeneous. Hardly any measurable brightness variations in the 3 tool regions.

Bayer8 to RGB conversion

Modern industrial colour cameras can transmit their data in a variety of colour formats. However, the actual colour image produced by a single-chip colour camera is a greyscale Bayer mosaic image. In a typical pixel array on the sensor, colour filters on each pixel allow only red, green or blue light to pass through. The result is a rasterised greyscale image. The brightness of the grey tones corresponds to the intensity of the colour. Taking into account the respective pixel neighbours, the missing R/G/B values can be obtained and calculated for all pixels. Many colour cameras can perform a colour conversion (Bayer-to-RGB conversion) directly using an FPGA.

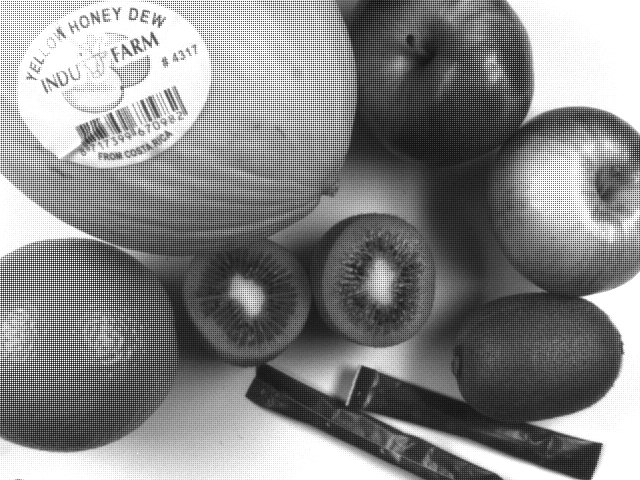

Raw Bayer image without colour conversion

(Enlarge image!) The RGB colour mosaic on the single-chip colour sensor produces a native greyscale image in which the R/G/B pixels are of different brightness. The image appears rasterised. The colour information can be calculated from this pattern.

Computed colpour image

Image calculated from Bayer image (8 bit) contains 24 bit colour information, but loses detail resolution due to Bayer pattern and has slight misinformation (colour fringes) at object edges.

Instead of a 24-bit RGB digital colour image, the image can often be transmitted as an 8-bit Bayer greyscale raw image. However, colour conversion must then be performed on a frame grabber or using PC software. The advantage of post-conversion is the higher frame rate that can be transmitted, as only 8-bit mono information needs to be transported, rather than 24-bit colour information. If the conversion is done in the camera, neither the frame grabber nor the computer's CPU is stressed.

Other typical correction options

Contrast adjustment

Contrast adjustment changes the difference between the brightest and darkest areas of an image, highlighting important details, which is important in quality control to help identify errors or irregularities.

Other tonal adjustments include adjusting the brightness and contrast values of an image to optimise the overall brightness and dynamic range of the image.

Colour corrections

Colour correction involves adjusting hue, saturation and brightness to improve or standardise colour reproduction. Without further optimisation, colour images often have a colour cast or the colours are not very saturated and easy to see. Colour correction options help to identify colours in dark and light areas of an image simultaneously.

These corrections are essential in the printing industry and many other areas where accurate colour reproduction is essential to ensure that the colours in the final product meet expectations.

Colour space conversion

Colour space conversion converts an image from one colour space to another, for example from RGB to YUV. This conversion is often used in image processing to meet specific colour design or data compression requirements, such as video compression or adapting images for different display technologies.

White balance

White balance corrects colour differences caused by different light sources to ensure neutral colours. White balance corrects colour variations caused by different light sources to ensure neutral colours. As the colour temperature can change very quickly under the influence of daylight, industrial cameras also offer the option of dynamic, permanent white balance.

Defect pixel correction

Defect Pixel Correction identifies and corrects defective pixels in an image sensor that can produce black or white dots in the image. In applications where the highest image quality is required, such as medical imaging or scientific research, this correction is essential to ensure that the images are error-free. Although the defective sensor pixels are not available for image processing, they can be interpolated from the surrounding neighbouring pixels and thus no longer interfere with the subsequent processing algorithm. The most disturbing pixel defects are those that are additionally charged due to insufficient or defective insulation on the semiconductor, and ruin the actual image information due to too many free charge carriers. These pixel defects appear as very bright dots in the image. If several such pixel defects occur, the image will look like a 'starry sky'. This is particularly important for infrared cameras, which often have many more defective pixels.

Enhance edge structures

This function emphasises the edges of an image by enhancing the brightness differences at the edges of objects. Edge enhancement makes the overall image sharper and clearer, making it easier to recognise objects and their properties, but should not be used for measurement applications!

Noise reduction

Various sources of noise such as photon noise, sensor dark current noise, digitisation noise or local noise of the sensor pixels due to small differences in sensitivity from pixel to pixel (photoresponse non-uniformity, PRNU) lead to noise effects in images. Modern cameras can compensate for noise using interpolation techniques ('denoising').

Need to buy the right camera?

Vision-Doctor.com is a private, independent, non-commercial homepage project and not a technology provider or system integrator. Suitable technologies and further professional support can be obtained from the companies & partners listed below.

If necessary, I will be happy to provide a quick recommendation, contacts and brief information.