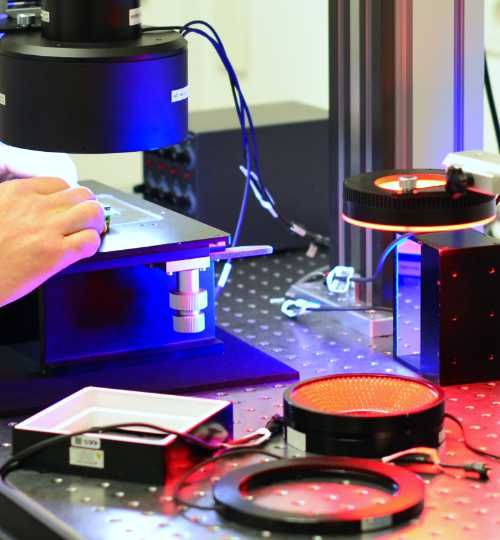

Proper lighting is an essential element in machine vision. It forms the basis for accurate and reliable inspections and plays a key role in the detection and analysis of faults and defects. Carefully selected lighting ensures uniform and optimal illumination of the inspection object, which significantly improves image quality and increases the accuracy of processing.

Without the right lighting, even the best cameras and image processing algorithms cannot deliver the best results.

What is the size of the field of view and the object to be inspected?

How far is the camera and lighting from the object?

What lighting types and light intensity is required for illumination?

How do the inspection features look like and with which lighting technique can they be detected?

Which material properties and surface characteristics does the object have?

Which colour does the part have?

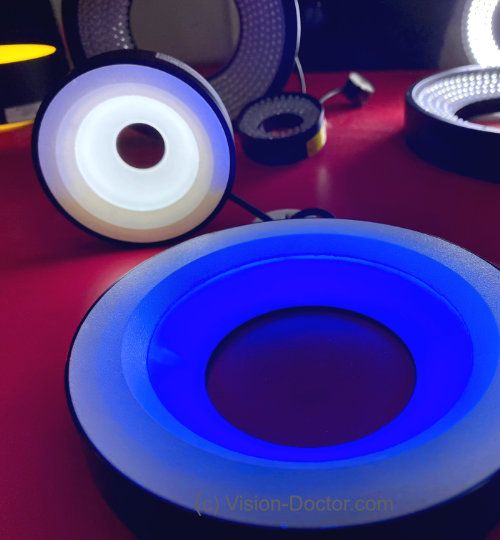

Which light colour is required? White, Red, Blue, Green? IR or UV radiation?

Any type of lamp can be used for lighting, as long as it does the job and fits into the system.

Today, however, LED lighting is the most common. They all have individual characteristics that make them more or less suitable for use.

Choosing the right lighting depends on a variety of physical factors that are often difficult to predict. Trial and error is explicitly allowed and is the basis for a stable application.

Vision-Doctor.com is a private, independent, non-commercial homepage project and not a technology provider or system integrator. Suitable technologies and further professional support can be obtained from the companies & partners listed below.

If necessary, I will be happy to provide a quick recommendation, contacts and brief information.