Illumination

IR Illumination

The wavelength range from about 780 nm to 1 mm, i.e. 1,000,000 nm, is called infrared radiation (it borders on the currently much-discussed range of terahertz radiation, which is used in so-called "body scanners").

IR radiation is often referred to as thermal radiation. In industrial image processing, however, most applications are in the near-infrared region, which covers the spectral range from 780 to 3000 nm.

Which hardware for inspecting in the IR?

The range between 780 and 1000 nm can still be inspected with normal monochrome CMOS cameras, whose sensitivity decreases progressively at this wavelength, but is in principle sufficient.

For longer wavelength IR ranges, Peltier-cooled sensors and special semiconductor materials (InGaAs) must be used. Cameras for mid-IR analysis are called thermal imaging cameras. Here, too, the optics are no longer made of ordinary glass, but of materials such as germanium.

Sony's SenSWIR family of sensors (IMX 990 / IMX991 / IMX992 / IMX 993) with a sensitivity of 400-1700 nm and a resolution of up to 5 megapixels are a good alternative.

For simple IR applications with 'standard' cameras, LEDs in the 870 or 950 nm range are therefore preferred. The longer wavelength is expected to reduce surface scattering and therefore improve the illumination of the target, but the sensitivity of the standard CMOS camera sensor is significantly reduced.

Typical spectra of IR LEDs for machine vision

Why use infrared radiation for inspection?

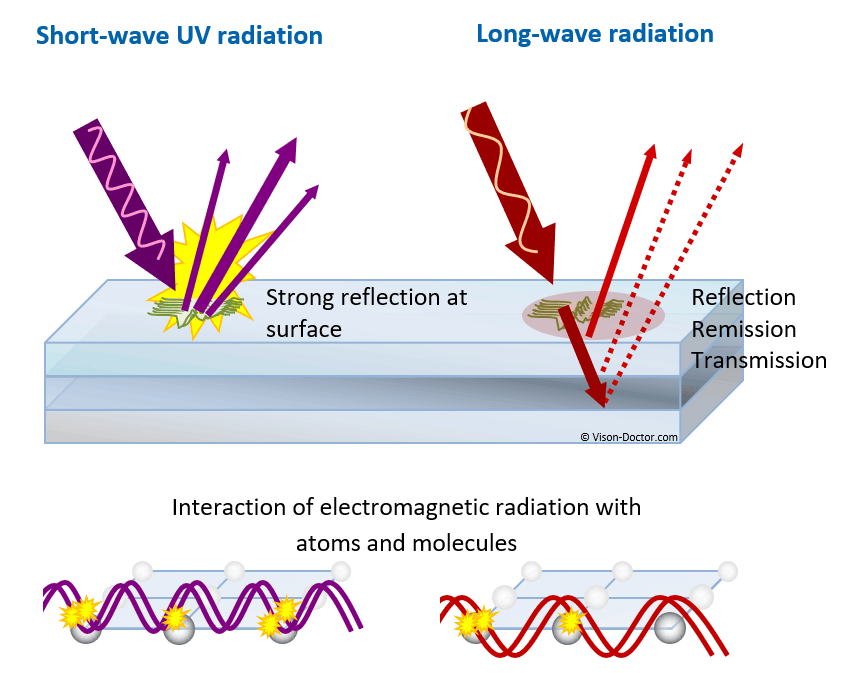

Longer-wave radiation is electromagnetic radiation and therefore oscillates less frequently than shorter-wave radiation and thus generates less interaction with the material.

It is therefore capable of penetrating deeper into the material and generates fewer surface reflections than short-wave light. When using IR radiation it is sometimes even possible to look through an object.

As IR radiation is invisible to the human eye, it is particularly suitable for workplaces where normal light would be particularly disturbing.

Surface effects when using IR and UV radiation

Typical inspection possibilities using IR radiation

-

Backlight inspection of materials that are not fully transparent but coloured, which no longer show any inherent colour in the IR and become (more) transparent.

-

Surface inspection despite printing or light soiling: printing colours become invisible except for black, cracks and surface defects can be detected.

-

OCR applications on banknotes, credit cards, etc. Caution: Inkjet inscriptions (expiry date, etc.) are often no longer visible!

-

Applications as usual, but in combination with a daylight blocking filter you can now work independently of room light.

-

Applications as usual without affecting the operator, e.g. at manual workstations.

Conventional illumination vs. IR illumination

Daylight - RGB

Daylight - Mono8

IR LED with 890nm

Daylight - RGB

IR LED with 890nm

Daylight - Mono8

Important for Machine Vision

- Infrared radiation is not visible to the human eye. IR radiation is indeed not very energised, but in the long term it can cause headache, warming of the receptors in the human eye and thus harm. However, this does only happen when using very intense light sources, directly looking into the lighting and over many hours. In case of smaller industrial LED lighting, this does usually not apply. Housing the test area is always recommendable for a number of reasons and solves these problems. Please thoroughly acquaint yourself with the topic (e.g. DIN EN 12198, DIN EN 14255-2 and BGI 5006)!

- If possible, clock the industrial IR illumination. In this way, unnecessary light emission and safety discussions (!) are avoided. A few inspections per second with an operating time of a few milliseconds are normally absolutely harmless.

- The use of narrow-banded band-pass filters or colour filters prevents interference caused by daylight.

- IR-corrected, optimised lenses generate perfect images. Normal standard lenses are not corrected for infrared light, the focal length for this radiation invisible to the eye can significantly deviate due to chromatic aberration. The spectral transmission of lens coatings, too, must be adapted accordingly. Both may otherwise lead to blurred images.

- Please also observe that there is no IR cut filter in the camera. Most of the time it can be replaced by a clear glass version (otherwise the imaging scales of the optics would change).

- Observe the sensor sensitivity of the camera used. There are considerable differences. The use of a special IR camera would be ideal.

- Attention: Applications using polarised light and polarisation filters in front of the optics CANNOT be realised by means of infrared radiation, as polarisation films are typically effective between 400 and 750 nm.

- Attention: inkjet imprints (best-before date) on groceries, for instance, as well as prints on thermopaper (such as cash slips, etc.) simply vanish in the camera image when illuminated using infrared radiation.

Colour image

Image contains colour information of visible light spectrum.

Infrared image

Coloured imprints typically disappear in IR. But here the black has also disappeared.

Need machine vision lighting ?

Vision-Doctor.com is a private, independent, non-commercial homepage project and not a technology provider or system integrator. Suitable technologies and further professional support can be obtained from the companies & partners listed below.

If necessary, I will be happy to provide a quick recommendation, contacts and brief information.