CMOS sensors have become an integral part of industrial imaging. In conventional camera technology, they have now replaced CCD sensors 100% (with perhaps the exception of a few scientific applications).

For decades, they had the (justified) reputation of producing noisy images, having many pixel defects and being less sensitive to light.

However, all these drawbacks have been continuously compensated for by improved manufacturing techniques, micro-lenses on the pixels (to increase the light-sensitive area) and back-illuminated CMOS sensors (back-illumination of the sensor through a very thin substrate).

Today, stacked photodiodes, microlenses and high quality readout circuitry provide fantastic light sensitivity.

Image sensors use the photoelectric effect to convert photons into electrical charges. In CMOS (Complementary Metal-Oxide Semiconductor) sensors, the conversion of charges into voltages takes place directly in the pixel, as opposed to CCD (Charge-Coupled Device) sensors where the charges are emitted sequentially and then converted into voltages. In CMOS sensors, these voltages are amplified, quantized and converted into digital values.

CMOS sensors are made up of millions of tiny photodiodes that convert light into electrical signals. When light strikes the sensor, it is converted into electrical charges (electrons).

A capacitor is connected in parallel with each photodiode and is charged by the photocurrent. The voltage generated is proportional to brightness and exposure time. Unlike CCDs, the electrons accumulated during exposure are not sent to a single readout amplifier, but each individual pixel is assigned an amplifier that makes this capacitor voltage directly available to the analogue signal processor. In the case of CMOS sensors, the light-sensitive diodes are connected to several transistors that convert the accumulated charges into measurable voltages.

This means that each pixel can be electronically read individually, without the need to shift as with CCDs. This results in less blooming when overexposed.

Modern CMOS sensors are characterised by high frame rates and outstanding image quality. This is mainly due to fast data processing and the ability to integrate many additional functions directly on the sensor chip, such as noise reduction, image pre-processing and analogue-to-digital conversion.

The high level of integration enables the development of high performance industrial cameras with low power consumption, enabling precise and fast image inspection. In addition, the scalable production technology of CMOS sensors enables the development of more cost-effective and compact vision systems.

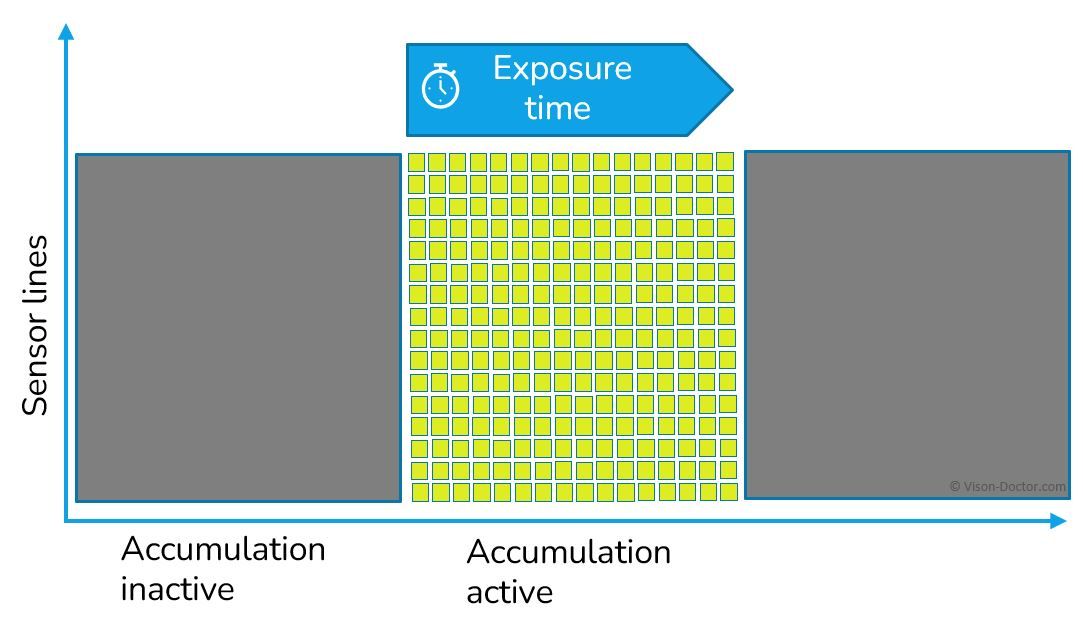

Like CCD sensors, modern CMOS sensors can also discharge all pixels simultaneously, record the image and read it out synchronously. These are referred to as global shutter CMOS sensors.

CMOS sensors with a rolling shutter have a different readout principle. Here, the image is exposed and read out line by line on a rolling shutter basis.

With a global shutter, all pixels are exposed and read simultaneously. This means that all image lines are exposed at the same time and read out simultaneously at the end of the exposure phase.

As all pixels are exposed at the same time, there is no distortion with moving objects. This results in more accurate images, especially with fast movements.

This technology is more complex and expensive, requiring more transistors and more complex electronics.

It can also lead to higher noise levels.

High-end industrial cameras today almost always use global shutter CMOS sensors.

With a rolling shutter, the image lines are read one after the other. This means that the exposure of the top line starts first and then continues line by line.

This method is the least expensive and generates less heat and consumes less energy due to the smaller number of transistors.

Moving objects can be distorted because parts of the image are recorded and read at different times. This leads to what are known as "skew" or "jelly" effects. These effects are particularly noticeable with fast movements.

With a global reset of the pixels, combined with a short LED illumination flash and ambient light shielding to prevent overexposure due to ambient light, moving objects can be effectively captured despite rolling shutters.

Rolling shutter sensors are generally avoided for industrial evaluation processes. However, there are many applications where this is not an issue and the price of the hardware is the main consideration. In surveillance technology, for example, SONY Starvis sensors with rolling shutters play a special role. These sensors are somewhat more sensitive than their counterparts with global shutter, but with the same pixel size.

Image looks normal.

Camera image is read out line by line with a time delay. Camera panning leads to a shift of the object edge (not to motion blur, which unfortunately dominates here)

Vision-Doctor.com is a private, independent, non-commercial homepage project and not a technology provider or system integrator. Suitable technologies and further professional support can be obtained from the companies & partners listed below.

If necessary, I will be happy to provide a quick recommendation, contacts and brief information.