It has never been easier to inspect not only the visible part of the light spectrum, but also other wavelengths. For a long time, cameras with special detectors were only used in a few special cases in machine vision. This resulted in expensive, customised solutions in very small quantities.

However, it is precisely outside the visible wavelength range that things can be detected that are invisible to the human eye.

Today, such applications are much easier to implement.

This is where SONY has been particularly helpful in recent years. The design of such UV and IR sensors is very simple for camera manufacturers, as these sensors are very similar to standard sensors in terms of design and electrical control.

Another example of high-end sensors for scientific applications or for UV and IR inspection is certainly the company Gpixel.

For a long time, conventional CCD camera technology was limited in its ability to detect short-wave UV radiation. This was due to the fact that the standard sensor glass blocked short-wave UV light. To overcome this problem, the sensor glass was subsequently removed and partially replaced with quartz glass, which, unlike conventional glass, is transparent to short-wave UV light.

Another method of detecting UV radiation was to use specially coated fluorescent layers on the chip surface. These layers allowed the UV radiation to be converted into a wavelength that could be detected by the sensor.

Today, detecting UV radiation has become much easier. Thanks to the high UV sensitivity of modern BSI camera sensors, the standard SONY IMX536 monochrome sensor can also be used for UVA applications (315-400 nm). This opens up new possibilities in areas such as microscopy and astronomy.

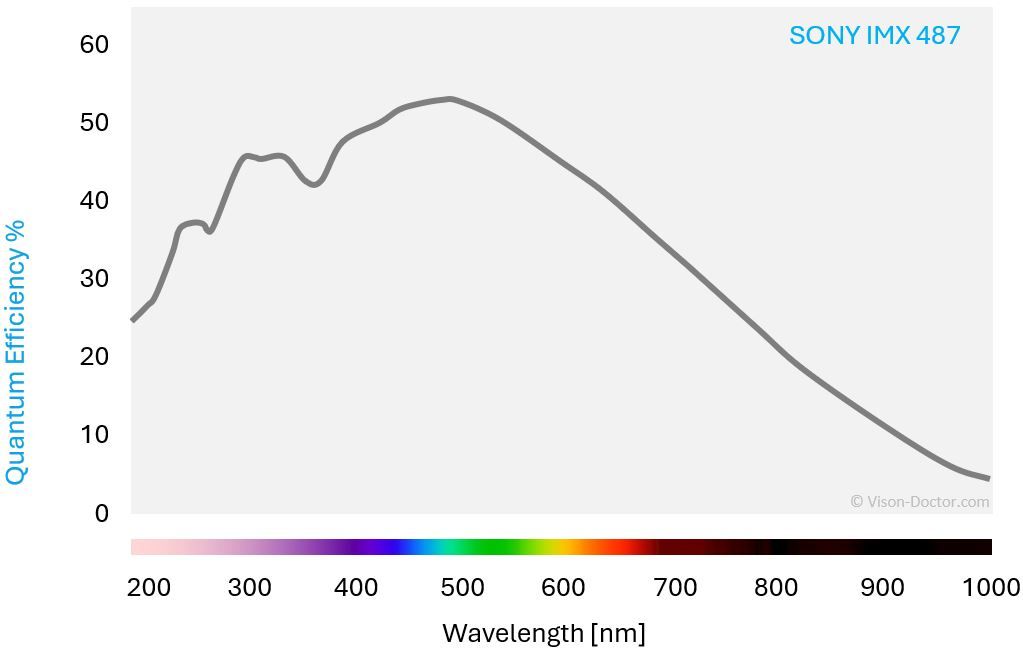

For more demanding UVB (280-315 nm) and UVC (<280 nm) imaging applications, the SONY IMX487 offers significantly higher quantum efficiency. This makes it an excellent choice for applications where high sensitivity and precision are required, such as medical imaging and forensics.

An interesting aspect of UV imaging is its application in materials science, where it is used to visualise surface structures and defects that are visible in the developing material.

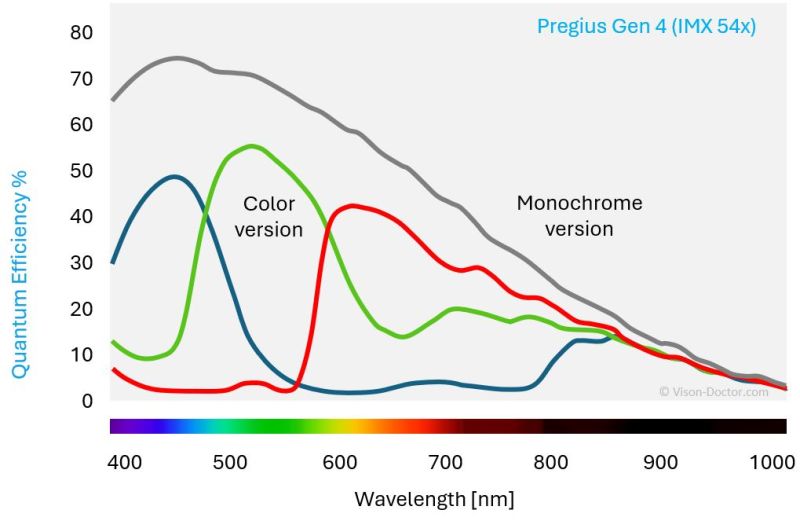

Modern, conventional CMOS sensors have traditionally been used for inspection in the visible spectrum (VIS) between 400nm and 700nm. These sensors are capable of providing accurate intensity data, with monochrome camera sensors typically providing intensity data with a resolution of 8 bits up to 12 bits for standard uncooled cameras.

Another advantage of CMOS technology is that the monochrome versions can be used in the spectral range up to 1000 nm (VNIR = Very Near Infrared) without any special modifications. This opens up additional applications in industrial inspection and agriculture, where near-infrared light is used to analyse material properties such as moisture and composition.

For low-cost IR applications, simple IR illumination using infrared LEDs in the 850 to 920 nm range is sufficient. This is complemented by specially coated IR-compatible optics tuned to these wavelengths. Such solutions are particularly popular in security surveillance and in the automotive industry, where they are used for night vision and driver assistance systems.

InGaAs detectors for NIR/ SWIR

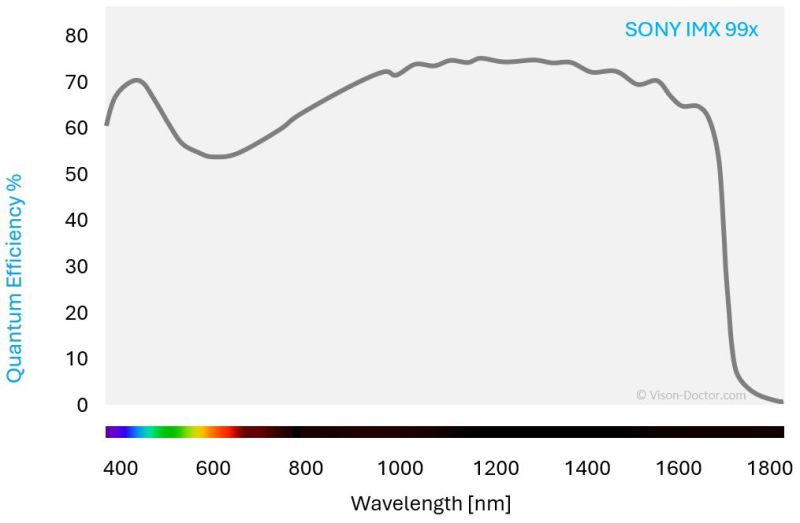

A particularly powerful infrared sensor that has gained in importance in recent years is based on indium gallium arsenide, often abbreviated as InGaAs. InGaAs sensors are sensitive to infrared light in a wavelength range that is relevant to many applications, particularly in the near infrared (NIR) range between 0.9 and 1.7 (or 2) micrometres.

The operation of InGaAs infrared sensors is similar to that of sensors in the visible spectrum and is based on the photoelectric effect. When infrared light strikes the sensor, electrons in the semiconductor material are excited and begin to move. This generates an electrical signal proportional to the intensity of the incident IR radiation. This signal is detected by a readout circuit, typically a classic global shutter CMOS sensor. The CMOS sensor is contacted with the IR-sensitive InGaAs layer via indium bumps or modern copper structures.

Today, InGaAs sensors are available 'off the shelf' with resolutions of up to 5 megapixels, making them attractive for a wide range of applications. They are widely used in spectroscopy for material analysis and chemical detection. They also play an important role in telecommunications, particularly in the transmission of data over fibre optic cables, as they are sensitive to the wavelengths used for data transmission.

InGaAs sensors are also used in military and civilian security technology, for example in night vision devices and surveillance systems. Their ability to deliver precise images in different lighting conditions also makes them indispensable for astronomical observations and in medical imaging, for example for skin cancer diagnostics.

One exciting area of application for InGaAs technology is agriculture. Here, the sensors can be used to monitor plant vitality and detect water stress. By analysing the reflected NIR light, farmers can make informed decisions to optimise yields and minimise the use of water and fertilisers.

Vision-Doctor.com is a private, independent, non-commercial homepage project and not a technology provider or system integrator. Suitable technologies and further professional support can be obtained from the companies & partners listed below.

If necessary, I will be happy to provide a quick recommendation, contacts and brief information.