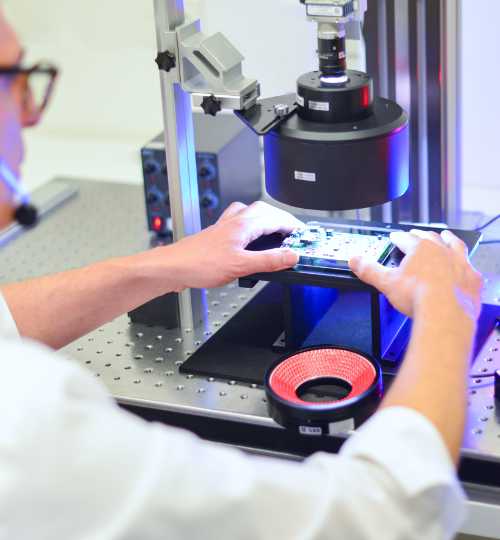

Production errors occur. Objects need to be detected. A component needs to be accurately measured. Production steps are monitored and readjusted. Fonts and codes are to be read. Where do anomalies occur?

The implementation of such a task can be very complex. What does the quality inspector really mean when he talks about a "component measurement"? What are the technical limits? Under what conditions can this be done?

Again, the "Specifications for the Planning and Implementation of Vision Systems (VDI / VDA / VDMA 2632-2)" provide a lot of information on what needs to be considered.

Feature detection (presence/absence)

Dimensional testing / "pseudo-measurements

Defect detection

Contour and deformation check

Object Search & Pick & Place

Optical Character Recognition / Verification (OCR / OCV)

1D and 2D code reading and grading

Colour identification

Print inspection

Deep Learning classification, Anomaly detection

"Real" (metric and calibrated) measurements

Measuring length, width, height

Angle, rotation, parallelism

Surface roughness (Ra, Rz values etc)

Volume measurements

1D / 2D code verification (calibrated, 15415. ISO TR 29158, AIM DPM)

Radiometric, standardised light measurements

Colour measurements with standardised colour spaces

Is all this really necessary? What is your task? What tolerances are desired or required?

Is it enough to say that the component is bent by approx. 2 degrees and is too long or too short by this value, deviating from the ideal, or does this have to be strictly metric?

Address these topics! Offline laboratory procedures under standard conditions are a different world, inline camera tests are often limited and difficult to replicate.

Based on the end customer's specifications, the service provider can develop a solution for the desired application.

Close consultation between the customer and the client helps here. For example, end users may not be able to provide all the information required for a specification. The end customer's preferences will also help the integrator to find a suitable solution for the customer.

Full description of the inspection task

Developed solution for this task

Definition of the necessary hardware setup

Used inspection algorithms

Mechanical setup for integration

Interfaces and communication

Calibration & capability verification methods

Information about the user interface

Details on installation, commissioning & maintenance

Time schedule for the project

Vision-Doctor.com is a private, independent, non-commercial homepage project and not a technology provider or system integrator. Suitable technologies and further professional support can be obtained from the companies & partners listed below.

If necessary, I will be happy to provide a quick recommendation, contacts and brief information.