Systems

3D Strip light projection systems

Strip light projection is a proven method for 3D measurement and surface inspection in machine vision. It enables the precise detection of surface geometries and offers a wide range of applications in quality control and production.

When a structured light pattern is projected onto a three-dimensional surface, the lines are distorted according to the geometry of the surface. These distortions are then captured by a camera and analysed to determine the 3D coordinates of the surface.

Working principle of strip light projection

Structured light pattern projection

Fringe projection is the process of projecting a sequence of structured light patterns onto a stationary object. This is done using a Digital Light Processor (DLP), which generates the pattern sequences and projects them onto the object.

Typical methods

There are two common methods of projecting light patterns:

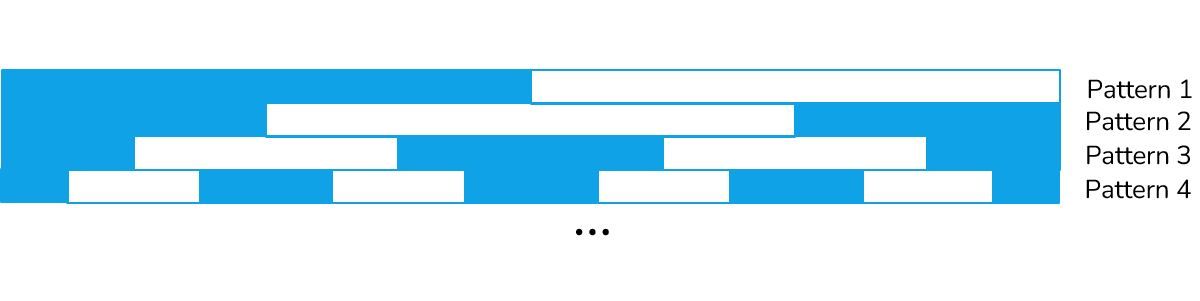

Sequence of line stripes: a series of a few to often 16 frames with line stripes of different widths are projected onto the object.

Phase-shifted sinusoids: A series of phase-shifted sinusoids can also be used to provide accurate measurements.

Deformation detection

The projected light and shadow transitions on the object are captured by a 2D camera (either monochrome or colour). This camera records the deformation of the light patterns caused by the object geometry.

3D reconstruction of the point cloud

The captured images are analysed by image processing software to reconstruct the surface structure of the object. The deformations of the light patterns are used to create a 3D point cloud that accurately reflects the geometry of the object.

Strip light (slow motion)

Pattern sequence

Typical 3D system using fringe projection

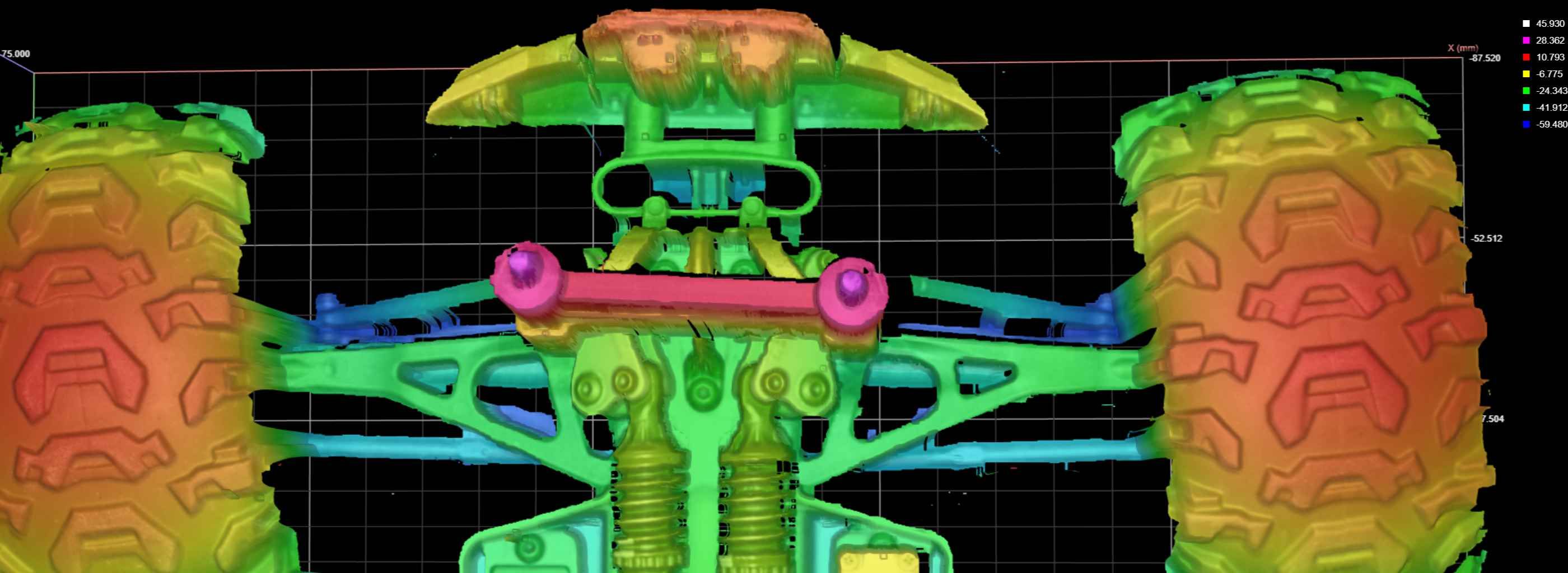

Scan data

- Animation -

Benefits of of strip light projection

1. Independent of the object's grey tones

A major advantage of stripe projection is its independence from the grey tones of the object. The method works mainly with height information and can therefore perform accurate measurements and analyses regardless of the brightness or colour of the material.

2. Scanning at standstill

Fringe light projection enables scanning at rest, i.e. no additional movement of the object or sensor is required. This simplifies the measurement process and increases the stability and accuracy of the measurements.

3. High Z accuracy

High Z accuracy is possible thanks to stripe light projection. This means that the technology can capture extremely accurate height information, making it ideal for applications where high accuracy is required.

4. Dense 3D point clouds

This technology provides 3D data for each individual sensor pixel, resulting in extremely dense 3D point clouds. These point clouds provide a detailed and comprehensive representation of the object surface, which is particularly useful for quality control and surface inspection.

5. Grey tone intensity image information

In addition to height information, intensity image information can also be captured. This allows further features of the object to be analysed using traditional 2D vision tools.

Potential disadvantages

1. Requirements for extended standstill

The target must not move or vibrate during the exposure sequence. Any movement can affect the accuracy of the measurements and lead to incorrect results.

2. Longer acquisition time

A complete 3D reconstruction often requires 12 to 16 images, sometimes with several additional exposure times. This can lead to longer scan times, especially if longer exposure times are required.

3. Occlusions

The angle between the light source and the camera can cause shadows that affect the measurement. A possible solution is to use dual head sensors to compensate for this shadowing.

4. Reflection problems

Reflections from shiny or reflective surfaces can cause problems and affect the accuracy of measurements. Special measures to reduce reflections are required to achieve optimum results.

Need help selecting a system?

Vision-Doctor.com is a private, independent, non-commercial homepage project and not a technology provider or system integrator. Suitable technologies and further professional support can be obtained from the companies & partners listed below.

If necessary, I will be happy to provide a quick recommendation, contacts and brief information.