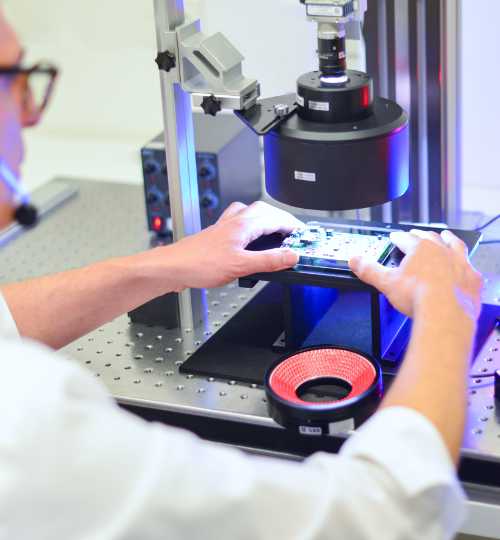

For several decades, camera-based optical inspection technologies have been used in automation, transportation, food production, testing but also increasingly in non-industrial applications.

In addition to a wide range of application fields, the utilized camera technologies and system solutions have also significantly improved. At the beginning of the 2000s, for example, mainly PC-based systems with 2D monochrome cameras were still in use.

There are many pitfalls in the decision-making process for camera technologies

In addition to the actual inspection task, many other topics must also be taken into account.

For example, your task is to measure a component to 100 µm and you have already selected the suitable hardware and software components. But many stumbling blocks can potentially be found here:

There are many such potential pitfalls....

Details about the test object

Number of component types and variations

Features to be inspected

Cycle and inspection times

Required data interfaces & communication

Machine effects

Environmental factors

General project information

Budget, costs

Timing of implementation, procurement times for components

System vailidation precedures

The guideline VDA / VDI / VDMA 2632-2 helps them in a perfect way to question the requirements and complexity of the needed camera systems. The VDI/VDE (Gesellschaft Mess- und Automatisierungstechnik), in cooperation with the VDMA (German Engineering Federation), has created an extremely useful guideline that is equally suitable for customers and system suppliers and offers a questionnaire that serves as a checklist for all these topics and provides many examples.

No dry, vague standard that beats around the bush. An investment of around 70 euros that is extremely worthwhile!

What is to be tested, under what conditions? Exact specifications from the end customer, what he expects

What a possible solution of the supplier could look like, with which technology, in which time and cost frame, taking into account all customer requirements.

Without exact specifications, planning and implementation is extremely difficult and may lead to project delays, cost explosions or, in the worst case, to unsuitable inspection systems.

Vision-Doctor.com is a private, independent, non-commercial homepage project and not a technology provider or system integrator. Suitable technologies and further professional support can be obtained from the companies & partners listed below.

If necessary, I will be happy to provide a quick recommendation, contacts and brief information.